|

On June 28, 2017 Flight Rail Corp. received a letter from three students in the Netherlands with questions about building a small scale atmospheric train. They began conversing with Flight Rail Corp.'s Engineering Manager, Eric Schlienger Ph.D. regarding their class project: Wednesday, June 28, 2017 Hello, My name is Remco Gloudemans, I'm 17 years old, I live in the Netherlands and I'm doing a school project with two friends. We saw a video of your train and we thought it was a great project for us. We are now trying to build a train by ourselves because we think it is a great train for the future. We only have some problems. We made a scale model of 70 centimetres (2 feet 39⁄16 inches). This model was working. (You can see in the video in the appendix.) Now we are trying to make a bigger model of 4 metres (13 feet 131⁄64 inch) but the model isn't working. Could you tell me how we could make a better or good scale model? Thank you in advance, Kind regards, Remco Gloudemans Thursday June 29, 2017 Dear Remco Thank you for your interest, I am certain you will find this to be an interesting project. I assume that you are only talking about a difference in the length of the tube and changing that length from 70cm long to 4m long. It looks like the diameter of the tube is about 5cm, and I assume that has not been changed. The only difference the length of the tube should make is that it might take a longer time for the train to start moving since your vacuum pump might require more time to remove the air from the tube in front of the train. Some things to check: Does the train car move as freely on the new tube as it did on the first one? With the vacuum pump running, if you use your hand to cover the tube behind the train, can you feel a vacuum being pulled? If so, and you wait a minute then remove your hand, does the train move? It might be that your vacuum seal in the tube is not good enough. Without the train on the tube, have you been able to verify that the vacuum pump is working as well as it should be? Are all of your plumbing connections tight? My guess is that your problem is either more friction than you had before, a vacuum leak, or the pump is not operating properly. As mentioned earlier, the only scaling issue with increasing the length of the track should be in the time it takes for the train to start moving. Please let me know how you progress and please let us know if we can provide you with any further assistance. Regards, Eric Schlienger Ph.D. Flight Rail Corp Thursday, June 29, 2017 Dear Mr Schlienger, Thank you very much for your quick response. The diameter of the small tube (70 cm) was 3,03 cm and the diameter of the big tube (4 metre) is 3,36 cm. Because of the change of the diameter we changed the thrust carriage. We made the thrust carriage out of heating tube isolation and it worked in the small tube and a few times in the big tube. The answers on your questions: Yes, the train car moves as freely as it did on the first tube. Yes, you can feel the vacuum when the pump is running. Yes, we were able to verify that the vacuum pump is working as well. We don't have plumbing connections because the tube is made out of one piece of PVC. With the help of your information ánd questions we were able to make the train ride again! Thank you very much! We think our thrust carriage was too wide for the tube so there was too much friction and it wasn't moving. We made the thrust carriage thinner so air could pass along the tube. We're looking forward to hearing your reaction, Kind regards, Remco Gloudemans Friday, June 30, 2017 Good to hear it! I am glad you were successful. I have included a photo that shows one of our early test systems. This system uses a 30cm diameter tube. As you can see, it is powered by 3 vacuum cleaners. If you have a vacuum cleaner available to use in your experiments, you might be surprised at how well it works. We found that the system operates most effectively when both sets of magnets are supported so that they do not contact the power tube. If the system design allows the magnets to pinch the power tube, then the friction can make motion very difficult. Regards Eric Friday, June 30, 2017

Hi Mr. Schlienger, We use a vacuum pump instead of a vacuum cleaner which works pretty fine as you can see in the video in the appendix. The pictures show our tube, the thrust carriage and the train car. We have lowered the magnets in the thrust carriage so they don't touch the tube. It works even better now! Thank you for your advice and interest in our project! We'll keep in touch Regards, Remco Friday, June 30, 2017 Remco, It looks great! I am impressed with your design and system. I mention the vacuum cleaner because of the typical pumping characteristics of a vacuum pump vs. a vacuum cleaner. I believe you will find that lower pressure that may be achieved using a vacuum pump cannot be effectively used due to the limited gas flow that your vacuum pump delivers. On the other hand, although only able to provide a smaller ultimate pressure differential, the higher gas flow available with a vacuum cleaner type blower may actually be better suited to the application. As an example, our large system out in the vineyard only achieves a maximum differential pressure across the thrust carriage of about 130 Torr. Our speed limitation is due to gas flow, not pressure differential. Although scaling (cross sectional area of the power tube vs. volume of gas which must be removed) has an impact, an experiment with a vacuum cleaner might result in a higher velocity than you have at present. Keep me posted and good luck! Eric Thursday, July 6, 2017 Hello Remco, I have been out of town and I suspect that your project is now complete. I hope it went well. We would like to mention your experiments, may we use your video on our blog? There are multiple formulae for the train design and many of the are specific to what you are trying to determine. Train weight, track grade, top speed, acceleration, distance between pumping stations, leakage, wheel friction, seal friction, aerodynamic drag, distance between trains, temperature swing, etc. all factor into a successful design. The most important formula is the one for the cross sectional area of the power tube PI*R^2. This area used in conjunction with the pressure differential provided by the pump determines the static force available to begin moving the train and must exceed the breakaway force of the system in order to allow motion to start. Once motion starts, the ability of the pump to move air must be compared to the maximum achievable pressure differential. This is where pumping curves become important and why a vacuum cleaner might have given you a higher speed, while your vacuum pump would have allowed the train to climb a steeper hill. Hopefully you were able to arrive at formulae sufficient to complete your project satisfactorily. Regards, Eric Friday, July 7, 2017 Hi Eric, We would be honored if you use our video on your blog! We've used the by you named formulas: they worked out really fine. We're now finishing our report. By the time you'll read this, it will be done. Thank you very much for all your helpful advice, regards, Remco  Having seen our website videos, Alex Davies, Transportation Editor at WIRED, contacted us about our efforts interested in the possibility of featuring the VECTORR technology on the WIRED site. We are so pleased that Alex and his staff made that happen! They created an amazing video and story about our system that was posted last Wednesday. Here's the link: https://www.wired.com/story/flight-rail-vectorr-atmospheric-railway-train/

Just found out today transit author Alan Kandel wrote articles about advanced transportation technologies that included our VECTORR system in the April 19, 2016 issue of CityMetric and the June 2016 issue of Rail Professional (Page 97). We are thankful to Mr. Kandel for writing these articles, and for including our technology in his ebook released in December 2013, "The Departure Track: Railways of Tomorrow". In his writings, Mr. Kandel takes a closer look at more advanced transit modes that could revolutionize travel in the future.

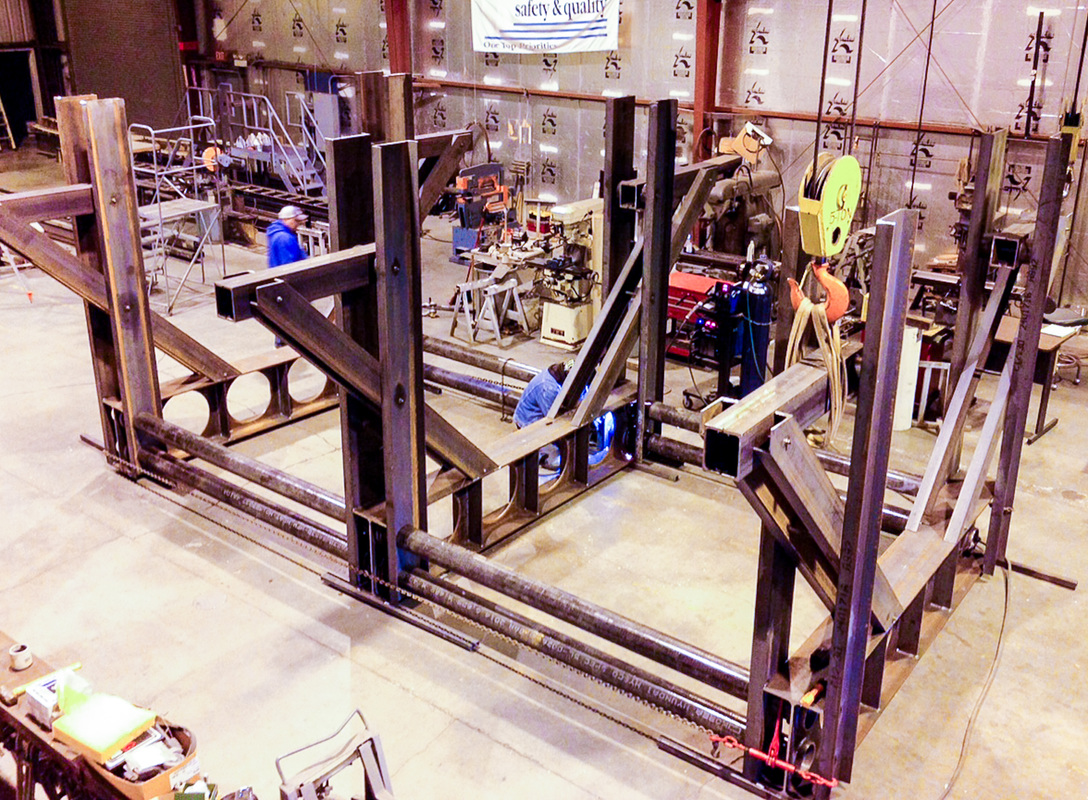

Flight Rail's Engineering Manager, M. Eric Schlienger Ph.D., with intern Luke Robinson installing automated controls on the 1/6 scale pilot model blower/changeover valve system.Recent advances in the Flight Rail pilot scale model include improved utilization of pumping energy. The initial proof of concept design operated with one side of the thrust carriage subjected to vacuum (or pressure), with the other side open to atmosphere. This represents a condition that will be commonly observed during full sized implementation, but does not take into account optimal energy utilization as the VECTORR unit passes a pumping station. On our test system when the unit (actually the thrust valve) passes the pumping station, the pumping station switches from pulling the unit (vacuum) to pushing the unit (pressure). For our initial trials, at the transition from vacuum to pressure modes of operation, the valve at the open end of the power tube would close, and the valve at the closed end would open. These valve motions support the transition of the operating mode from vacuum to pressure. However, our initial valve timing, (wherein the valve motion occurs as the thrust valve passes the pumping station inlet), does not take into account the loss of energy associated with the opening to atmosphere of the already evacuated portion of the power tube in advance of the thrust carriage. A new sensor suite, developed using Arduino boards by our summer intern Luke Robinson, has been added to provide accurate thrust carriage position sensing and precise pressure monitoring of the power tube. With the new position sensors in place, we are able to accurately gauge the timing of the transitions between vacuum and pressure at each of our inlet ports. The addition of the precision differential pressure sensors provide the ability to delay the opening of the power tube to atmosphere until the usable accumulated vacuum energy in front of the thrust carriage has been expended in the production of additional thrust. As a side benefit, the position sensors also provide velocity data. The combination of these sensors results in a smoother modal transition, a more uniform thrust profile and better energy utilization. We see this as a very positive development in the demonstration of the real world application of this technology.

Luke graduated from Ukiah High School last Spring and will be starting at Johns Hopkins University in the fall. His expertise is in electronics. As a freshman there he will be studying computer engineering. For three summers as a high school student, he has offered a camp for middle-school students on basic robotics using the Arduino development platform. These programmable processors, and the sensors and other hardware that interface with them, enable automation and control of a multitude of operations. His expertise with these devices is being applied to an upgrade of our 1/6 scale pilot model controls. We are increasing the automation of the valving on our power system to take advantage of the vacuum or pressure remaining in the power tube as the thrust carriage passes by the blower stations. Sensors along the power tube will report position and velocity of the thrust carriage, as well as residual vacuum in the tube to a programmable controller which will actuate individual valves to optimize efficiency. Luke brings a fresh perspective and a keen intellect to our team, if only for the summer. In addition to his work on the train controls, he has also been helping with the design, construction, and installation of an improved control and monitoring system for our small private water district. It is a pleasure for all of us here at Flight Rail to work with Luke. We will certainly miss him when he leaves this fall!

We are pleased once again to be featured on the front page of the Ukiah Daily Journal. Our local paper spotlighted Flight Rail in the Local Entrepreneurs section. The writer, Sarah Reith and photographer Chris Pugh did a great job! We appreciate the Ukiah Daily Journal's continued support of Flight Rail and our VECTORR technology.

We appreciate our local public radio station KZYX for hosting us on their Renewable Energy Hour this morning with Doug Livingston and Jeff Oldham. Doug and Jeff and callers into the station asked our Pilot Program Manager, John Reardan, great questions that facilitated discussion of our system's present and projected full-scale capablities.

Flight Rail Corp. presented the VECTORR technology at a Federal Highway Administration Exploratory Advanced Research workshop in San Francisco. The goal of the workshop was to promote information exchange and discuss factors that may help bring novel surface transportation modes for highway corridors to greater maturity. Those in attendance included U.S. Department of Transportation staff, academics, private sector representatives, and local and state government officials. This was a great opportunity for VECTORR to show how easily our technology can be built within or adjacent to highway right of ways.

|

Archives

July 2017

Categories |

RSS Feed

RSS Feed